The Reverse Osmosis system (RO) includes household revere osmosis system, commercial revere osmosis system and industrial revere osmosis system. This Kind of industrial reverse osmosis system can purify different source water like tap water, rainwater, city water, underground water.

Application: food industry, such as juice, milk,tea, infusion and cleaning for the hospital, etc.Popular Capacity: 250LPH, 500LPH, 750LPH, 1000LPH.

The 1000lph industrial water treatment systems reverse osmosis purification is the most frequently sold product of our enterprise and one of the most classic reverse osmosis water purification machines. Because its capacity, function and treated water quality meet the application in most regions, this product is sought after by our customers from different regions.Whether you are engaged in industry, medicine, cosmetics, or used in hospitals, schools, hotels where clean water is needed, you can use our product.

Operation

This machine is very simple to operate. We have professional technicians to provide you with video operation, and customers can come to our factory site to try to operate the water quality of the machine. Our reverse osmosis equipment can apply a series of different water quality in various regions, such as groundwater, brackish water, hard water, grey water, etc. PH range of raw water is 3-10, Water Pressure is the 3-5 bar and TDS of source water is about 100-1000ppm.Our professional technicians will customize the equipment for you according to your local water quality and practical application. We have provided more than 5000 reverse osmosis water purifiers for Asia (Malaysia, Thailand, Vietnam), Africa (South Africa, Senegal, Nigeria), South America (Chile, Argentina, Peru) and other regions. Ocpuritech is a symbol of building water purification equipment for more than 10 years. In China, we hope to receive your inquiry.

Advantage

1,High quality, low price and easy operation.

2,The water production is fast, and the desalination rate is as high as 98%.

3,We have the guarantee of ISO and CE certificates and have passed the field certification of SGS company.

4,It is widely used in all parts of industry.

Front view

Back view

Before we start,Prepare the machine before running then the RO system is connected to the raw water pipe to transport the water to the machine and connect the local power supply on the machine to install PP filter elements on the precision filter and RO membrane to the RO membrane housing. Finally, pure water is to prepare to store in a water tank.

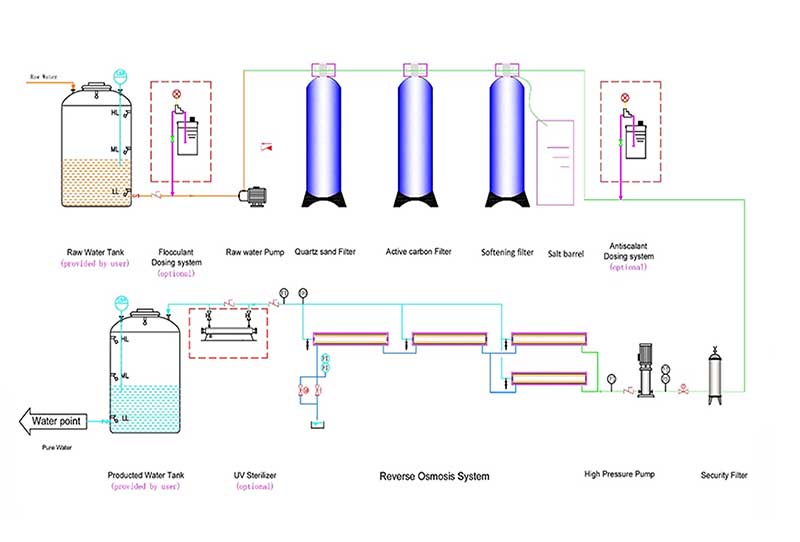

We can see that our raw water goes into the “raw water tank” first and filters the raw water through three major filters, namely quartz sand, activated carbon and softening. Both “raw water pump” and “high pressure pump” are designed to provide power for reverse osmosis. Then, at the most critical stage of reverse osmosis membrane, the water filter through reverse osmosis membrane and sterilized by ultraviolet sterilization lamp will finally produce filtered water, which is a complete filtration process of reverse osmosis equipment.

Finally,we should check the TDS value from the control panel and record the running water production, operating pressure, and water quality. Meanwhile, the specific data will be shown in the flow meter, pressure gauge, and conductivity controller.

RO Membrane

Dimensions:3 inches in diameter,12 inches in length.

Model:OV-L-4040

Desalination rate:99.4%

Operation:Automatic Control,Automatic flush

Memrane Housing Material:SUS304

Model:20”-blue-jumbo

Function: filtration

Inlet and outlet diameters: 3/4” or 1”brass thread

Material:PP filter cartridge

Working pressure:1.3

Ambient Temperature:15 ℃ – 40 ℃

Maximum Ambient Pressure: 1.0Mpa

When the density of the transported medium is greater than that of water,need to consider higher power pump

Remove sand,impurities accuracy 5um.

Remove the samll particiles such as small quartz sand,carbon particles,to ensure the outlet water pecision and protect the follow up high pressure pump and membrane.

Sand Filter:Using quartz sand and gravel to removing allphysical impurities larger than 10 micron by FRP or SUS tank with multi-port valve.

Carbon Filter:Using coconut-shell activated carbon to removechlorine,odor&taste by a FRP or SUS tank with multi-port valve.

Softener:Using cation resin to remove salts of calcium iron,magnesium that may form scale encrustations by a FRP or SUS tank with a multi-port valve.

Application

Our equipment can provide customers with a variety of application sites, among which drinking water is the most common application for our customers. In addition, we have also provided industrial reverse osmosis water purification systems for large villas, large water companies, fruit juice companies, cosmetics companies, chemical factories and other application sites. We will according to different water quality, Recommend the most accurate and suitable local water purification system for customers.

Packaging: Wooden Case, Carton Box or Export Neutral Packing

Shipping: We will choose the fastest with the cheapest shipping mode for you by air, sea or courier.

We have professional QC team to check the equipment’ s quality before delivery. And we could provide the free technical training.

1. Provide complete OEM or ODM water treatment solution based on your source water

2. Provide free technical training and full good after service.

3. We have the professional QC team to check the quality before delivery.

4. The durable High-impact carton to protect the products.

5. Reply in 24 hours.

6. Lead time for water filter cartridge is 5-7 working days

Lead time for the water treatment system is 7-15 working days

版权归千图网所有,盗图必究