An application of a reverse osmosis water treatment system in the Cosmetic Industry has been tied to two outcomes, an increased profit margin and healthier cosmetics.

The Reverse Osmosis process is designed to purify water by removing any impurities that are found in tap water, which includes metals, chlorides, nitrates, and other contaminants.

This process can be done on-site with a customized system, or it can be outsourced for installation at the factory. Each facility will have different needs when considering RO systems because each location will have different sources of contamination. Let’s dive into further details!

What is the Process?

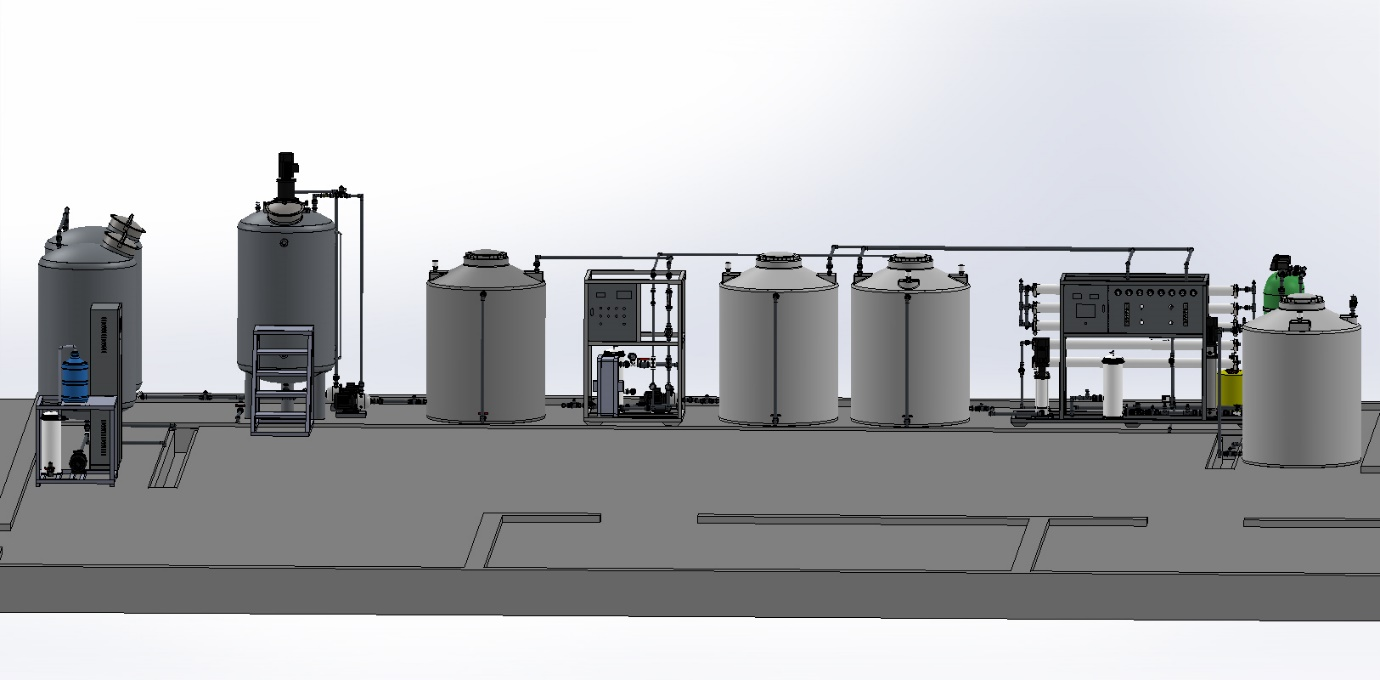

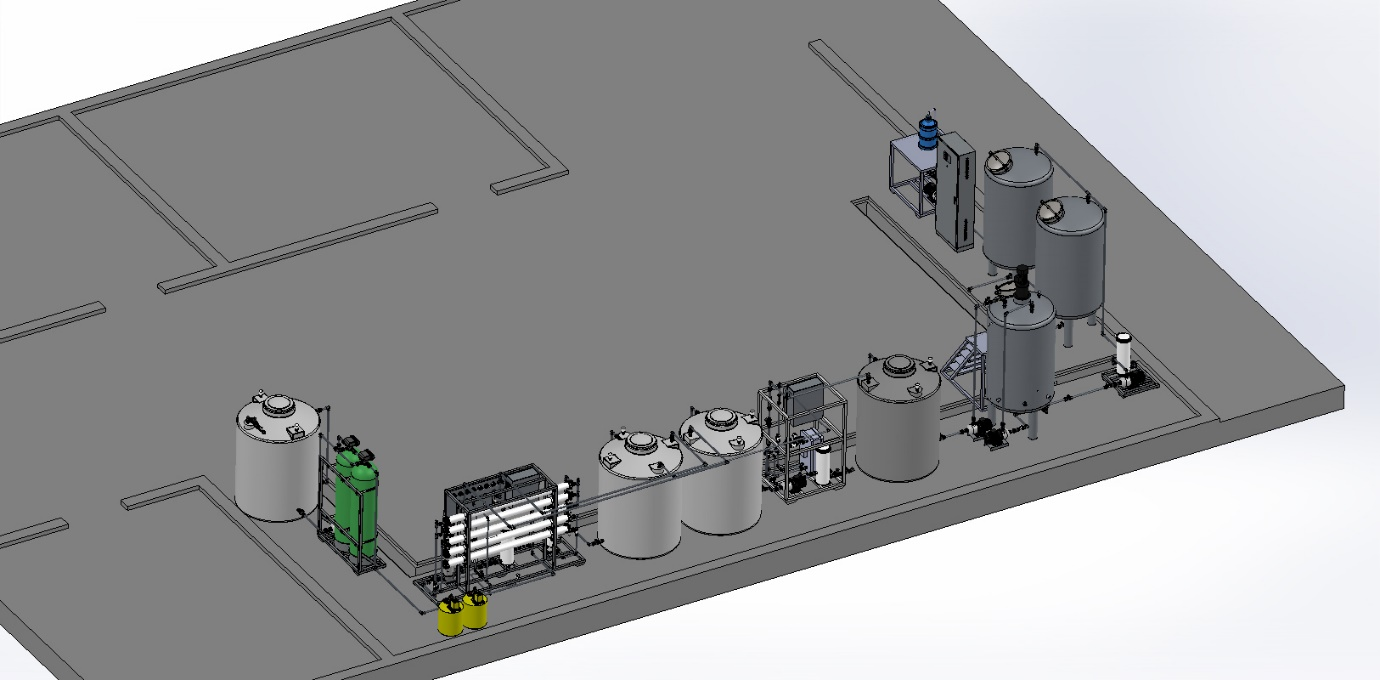

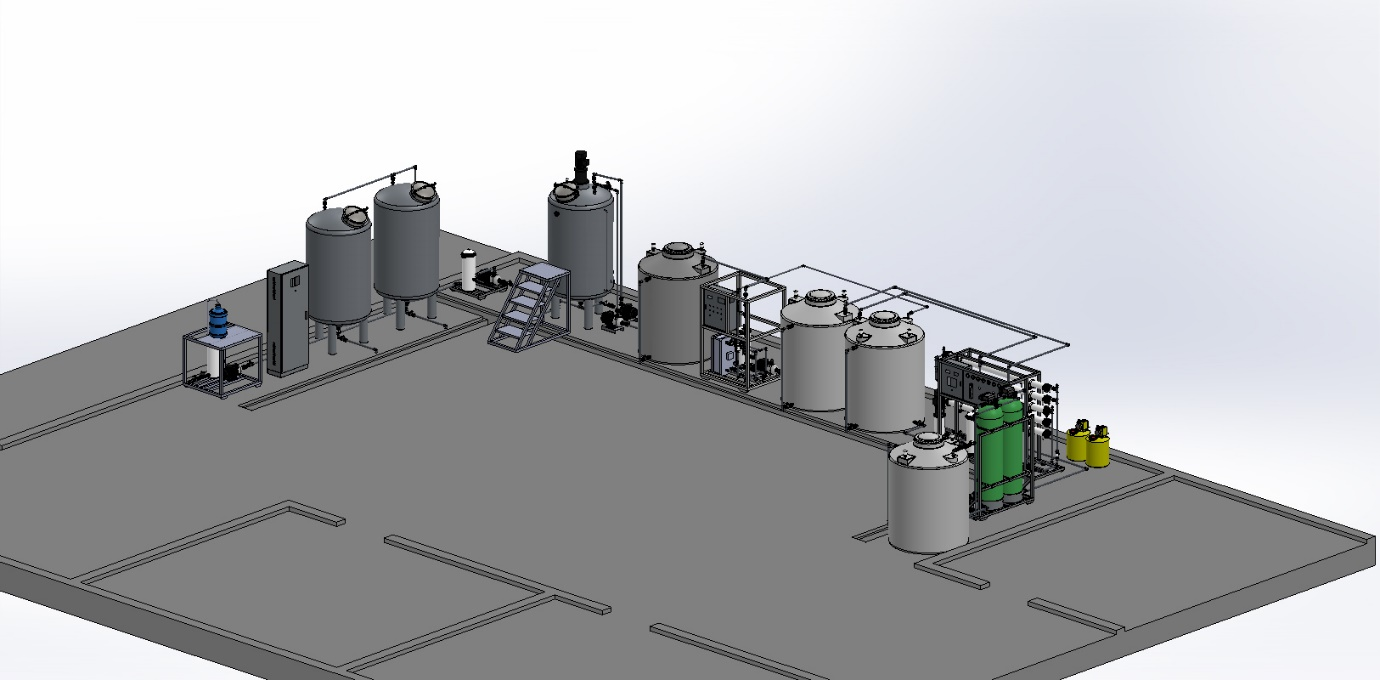

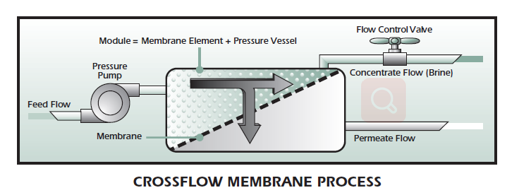

A reverse osmosis system has four main components: a pre-filter, pressure vessel, membrane filter, and post-filter. The source water is pumped into the pressure vessel, where it then passes through the membranes creating purified water on one side of the filter and contaminated or “concentrate” water on the other.

The process starts out by pretreating the water to prepare it for filtration. This is done by removing large particles and debris from the source through a pre-filter, which can include coarse screen filters or mesh screens that separate out larger impurities such as leaves and twigs.

The second step of this process is water flows into a filter tank or pressure vessel that contains reverse osmosis membranes through one port and the filtered feedwater from another. For smaller systems, a chamber in the vessel acts as both a filter tank and pressure vessel. The membrane is held between two rubber gaskets under tension from compression springs that keep it submerged below the feedwater level inside of the pressure vessel or filter tank.

The next,water leaving the membranes goes into collection tanks, where any remaining impurities are filtered out via a post-filter. This last step in the process is where an operator can add potassium permanganate to remove iron and hydrogen sulfide (rotten egg gas).

The RO system operates when there is pressure from both ends of the membrane, which causes water to pass through it, leaving contaminants behind. The end result leaves you with purified or “product” water.

What are the Benefits of Reverse Osmosis?

The main benefits that come with installing a RO system in your Cosmetic Factory include an increased profit margin and healthier cosmetics!

The first benefit is due to there being fewer impurities present in product water compared to source or tap water – which reduces costs by lowering raw material use and improving product quality. The second benefit is due to there being fewer impurities present in product water – which reduces the use of preservatives such as parabens!

Reverse Osmosis Systems can be customized based on your Cosmetic Factory’s specific needs, capacity, and location where it will be installed. It is important for operators to understand what is in their source water and how to go about adjusting the process flow according to these needs.

Water must pass through several filters before it enters your RO system, so knowing where impurities are coming from will help you get started on choosing the right filter media for pretreatment!

What are the Challenges?

The biggest challenge when it comes to Reverse Osmosis Systems is the cost. RO systems are an investment that will take a few months at least to pay off and require regular maintenance with added wear on components over time.

Another challenge might be an installation in tight spaces where a plumber or field service technician needs access for repairs and routine checks- although it is possible to install this system yourself.

The most important thing with RO systems is to remember that they need regular maintenance and require the use of replacement filters every few months or so, depending on usage levels!

It is also important for operators to understand what is in their source water, how it can be adjusted accordingly, and where impurities are coming from, as this will help you get started on choosing the right filter media for pretreatment.

What are the Solutions?

The first solution for this is to hire a company that specializes in Reverse Osmosis Systems maintenance and replacement filters. This will ensure the system runs at peak performance, reduce downtime due to repairs or filter changes, save you money on wasted water, and provide peace of mind knowing that your RO System is installed properly so it can run as intended.

The second solution is to make sure you are regularly replacing all the necessary filters every few months or so, depending on usage levels. It’s important for operators to have a clear understanding of where impurities are coming from in order to get started choosing filter media for pretreatment!

The last thing that can help with this process is ensuring that your RO system is installed properly so it can run as intended.