Industrial Reverse Osmosis (RO) systems stand at the forefront of water treatment technology, addressing the diverse needs of industries by efficiently removing salts and contaminants from various impure feed water sources. From municipal to brackish and surface water, these systems play a crucial role in ensuring the production of high-quality water suitable for a wide range of applications.

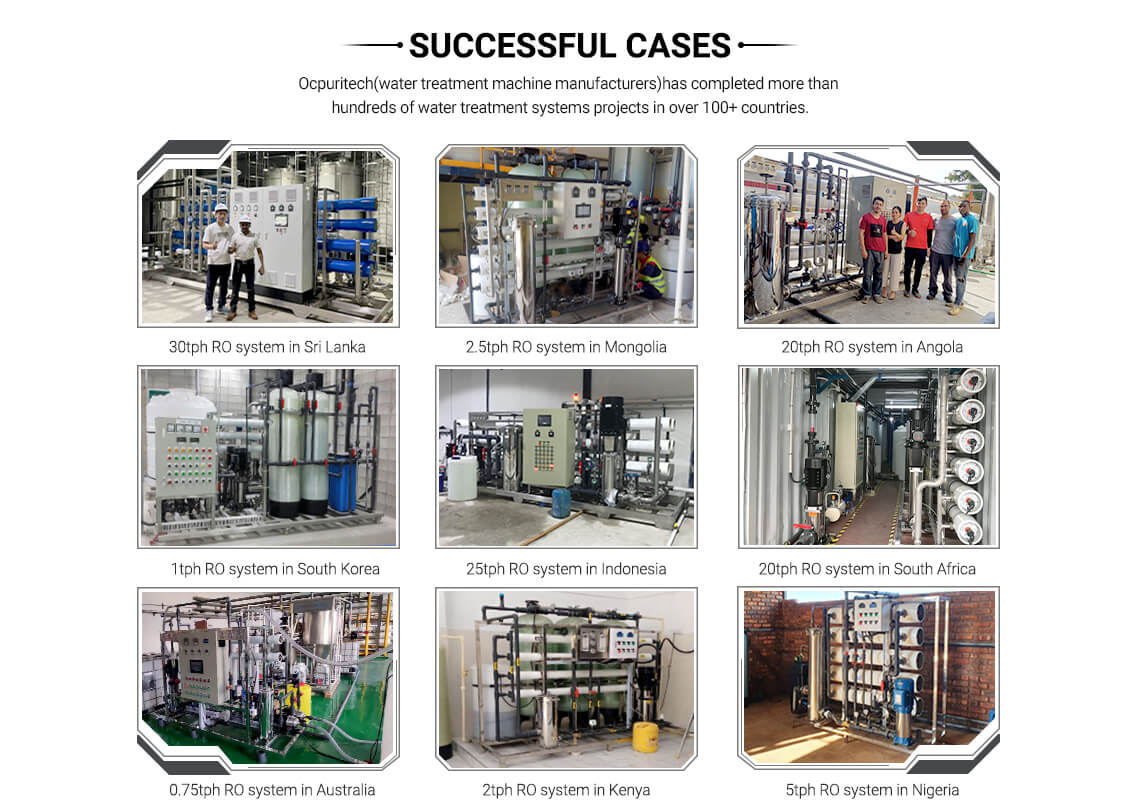

At OCPURITECH, we take pride in producing a comprehensive range of designed and custom Industrial Reverse Osmosis systems. With capacities ranging from 2000 to 180,000,000 LPH, our energy-efficient RO equipment guarantees the production of high-quality water at an economically affordable cost. Our commitment extends to delivering high-quality water even under challenging operational conditions and corrosive environments.

We understand that each water treatment application is unique. Therefore, our industrial RO systems are designed with selectable functional control features and additional apparatus, providing users with the capacity to customize their reverse osmosis machines. Whatever the specific requirements of your water treatment application, OCPURITECH’s industrial reverse osmosis system stands as the optimal solution.

Our TW SRO Series stands out as one of the most compact industrial reverse osmosis systems available. It comes equipped with media filters and chemical dosing systems (including pre-chlorination, antiscalant, dechlorination, post chlorination, and post pH adjustment), all customized to meet the diverse needs of individual customers and various water applications.

Featuring energy-saving 8040 RO membranes, the TW SRO Series is designed with a keen consideration for specific water challenges. Its attributes include robust construction, a user-friendly design, environmentally friendly materials, economic operation, and long-term reliability. Moreover, you have the flexibility to select the TW SRO system as your containerized reverse osmosis water treatment plant.

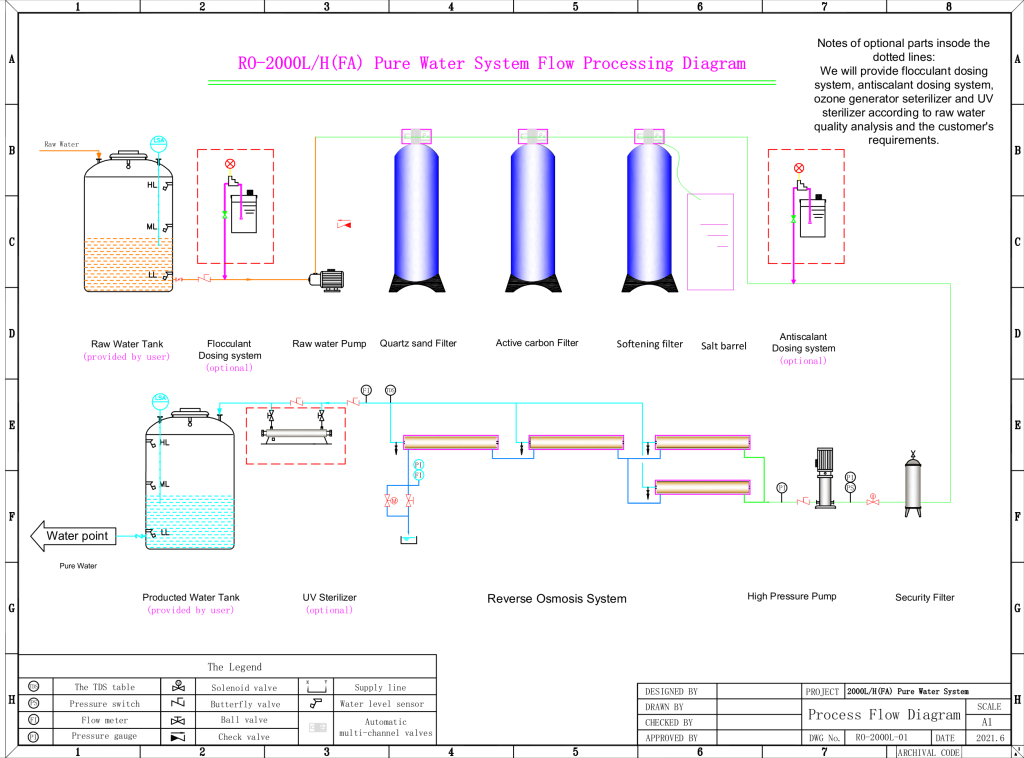

The industrial reverse osmosis plant includes multimedia pretreatment tanks, a water softener, antiscalant dosing system, antifouling dosing system, reverse osmosis unit with semi-permeable membranes, ozone generator, and ultraviolet sterilizers or post chlorination as post-treatment.

The process begins by sending feed water through a multimedia prefilter to remove particles larger than 10 microns. Subsequently, the water undergoes antiscalant chemical treatment to control hardness fouling that may damage the RO machine’s membranes.

These pretreatment options effectively remove hardness, chlorine, odors, color, iron, and sulfur. The water then enters the reverse osmosis unit, where a high-pressure pump applies extreme pressure to the highly concentrated solution, separating remaining salts, minerals, and impurities that the prefilter cannot catch. Fresh, potable water emerges from the low-pressure end of the membrane, while salts, minerals, and other impurities are discharged into a drain at the other end. Finally, the water passes through a UV sterilizer (or post chlorination) to eliminate any remaining bacteria and microbes.

The cost of an industrial reverse osmosis purification system is significantly dependent on feed water quality and the required product water quality. Several common pre and post-treatment components contribute to the overall cost, including chemical and pH dosing, media filters, carbon filters, water softeners, advanced controllers, TDS, pH, and conductivity monitoring, stainless steel skid or frame, and more.

The electrical power consumption of an RO system varies based on the plant’s capacity, measured in liters per hour or liters per day. Our RO water treatment system’s power supply range is 220V to 480V, with 50Hz or 60Hz.

In the realm of industrial water treatment, reverse osmosis systems have emerged as indispensable tools for purifying water. Their ability to deliver high-quality water, maximize efficiency, and contribute to sustainability has positioned them as a preferred technology in various sectors. By understanding the working principles, benefits, and considerations for effective implementation, industries can harness the power of industrial RO systems to optimize water purification processes.

Discover the efficiency and reliability of OCPURITECH’s industrial reverse osmosis systems. Our commitment to delivering high-quality water treatment solutions ensures that our systems are designed to meet the specific needs of diverse industries. From compact designs to energy-efficient operations, OCPURITECH provides customized solutions for your water purification requirements.

Key Features:

Whether you require a standard industrial RO system or a custom-designed solution, OCPURITECH is here to meet your water treatment needs. Contact us today to explore how our industrial reverse osmosis systems can optimize your water purification processes.