The main goal is to improve the quality of water by removing impurities such as microorganisms, organic matter and dissolved minerals from the water.

In the realm of beverage production, with a particular emphasis on juices, the Ocpuritech Water Treatment Company stands ready to supply cutting-edge Juice RO Water Treatment Systems. In an industry where water quality and purity are paramount, advanced water treatment systems are indispensable. The Juice RO Water Treatment System, leveraging reverse osmosis technology, emerges as a vital player in ensuring the highest standards of water purity. This article delves into the pivotal role of water treatment in the beverage sector, the intricacies of reverse osmosis, and the manifold advantages of incorporating a Juice RO Water Treatment System into juice and beverage manufacturing processes.

Water Treatment’s Crucial Role in the Beverage Industry

Central to the production of juices and other beverages is the use of water in various processes, including preparation, cleaning, disinfection, and bottling. The quality of water directly impacts the taste, color, and overall quality of the final product. Undesirable elements in water, such as dissolved minerals, organic matter, bacteria, and viruses, can significantly alter the flavor and appearance of beverages. Hence, effective water treatment systems are not just beneficial but imperative for juice and beverage manufacturers striving to maintain the highest standards of water purity.

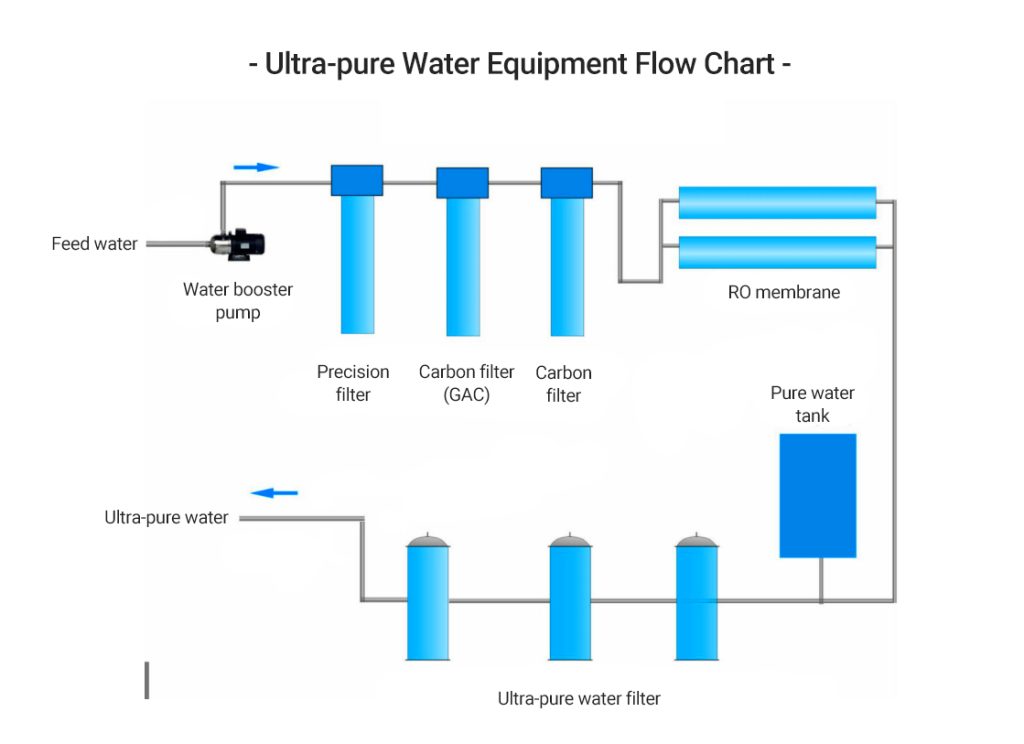

Unpacking Reverse Osmosis (RO) Technology

A widely adopted technology in the beverage industry, reverse osmosis employs a semi-permeable membrane to selectively remove impurities from water. This membrane acts as a barrier, allowing only water molecules to pass through while obstructing contaminants. Through the meticulous process of reverse osmosis, dissolved minerals, organic matter, bacteria, viruses, and other impurities are efficiently separated from water, resulting in purified water of superior quality. The Juice RO Water Treatment System harnesses this technology through its high-pressure pump system, membrane filtration pretreatment system, membrane valve frame system, backwash system, CIP chemical cleaning and dosing system, control system, and piping system—all working synergistically to ensure operational efficiency and reliability.

Benefits of Embracing a Juice RO Water Treatment System

1.Elevated Product Quality:

The primary objective of the Juice RO Water Treatment System is to enhance the quality of the final product. By eliminating impurities like dissolved minerals, organic matter, and microorganisms, the system guarantees that the water used in juice production is pure and free from contaminants, resulting in a consistently superior product.

2.Optimized Production Efficiency:

The system streamlines the production process by providing a dependable source of purified water. Operating with efficiency, it minimizes water wastage and maximizes water recovery, contributing not only to cost-effectiveness but also to environmental sustainability.

3.Adherence to Quality Standards:

In an industry where strict quality standards are non-negotiable, implementing a Juice RO Water Treatment System aids juice and beverage manufacturers in meeting regulatory requirements for water purity. It ensures that the water used in the production process aligns with the necessary criteria for taste, odor, color, and safety.

4.Cost Savings:

Investment in a Juice RO Water Treatment System translates to long-term cost savings. By producing purified water on-site, juice and beverage factories can eliminate the need for purchasing expensive bottled water or relying on unreliable water sources. The system’s efficiency and low maintenance requirements further contribute to cost-effectiveness.

5.Versatility and Customization:

Tailored to the specific needs of juice and beverage factories, Juice RO Water Treatment Systems offer versatility and customization. They can be adjusted to accommodate different production capacities, water quality requirements, and budget considerations, allowing manufacturers to optimize their water treatment processes.

Implementation and Key Considerations

When integrating a Juice RO Water Treatment System, several crucial factors merit consideration:

1.Water Quality Analysis:

A thorough analysis of incoming water quality is indispensable to determine the appropriate treatment processes and system configuration. Factors such as the presence of dissolved minerals, organic matter, and microorganisms must be assessed to ensure the system’s effectiveness.

2.System Design and Components:

The design of the Juice RO Water Treatment System should align precisely with the specific requirements of the juice and beverage factory. This involves selecting suitable components, such as high-pressure pumps, membranes, valves, and control systems, to achieve optimal performance and efficiency.

3.Maintenance and Monitoring:

Regular maintenance and monitoring are essential to ensuring the continued performance of the Juice RO Water Treatment System. This includes routine checks, membrane cleaning or replacement, and the continuous monitoring of water quality parameters, ensuring the system’s efficiency and lifespan.

Conclusion

In conclusion, the implementation of a Juice RO Water Treatment System stands as a cornerstone for juice and beverage manufacturers committed to delivering products of the highest quality and purity. Leveraging reverse osmosis technology, these systems effectively eradicate impurities from water, ensuring that the final product aligns with the stringent standards of the modern market. With enhanced product quality, increased production efficiency, and adherence to quality standards, juice and beverage factories can thrive in a competitive industry. Through investment in a Juice RO Water Treatment System, manufacturers gain not only cost savings but also versatility and customization tailored to their specific needs.