With the advancement of hydrogen production technology, ultrapure water equipment, as an indispensable component in the electrolysis of water for hydrogen production, is gradually becoming a mainstream device in the hydrogen production industry. This article will delve into electrolysis technology, especially alkaline electrolysis and Proton Exchange Membrane (PEM) electrolysis, with a focus on highlighting the crucial applications of ultrapure water in these processes.

ith the advancement of hydrogen production technology, ultrapure water equipment, as an indispensable component in the electrolysis of water for hydrogen production, is gradually becoming a mainstream device in the hydrogen production industry. This article will delve into electrolysis technology, especially alkaline electrolysis and Proton Exchange Membrane (PEM) electrolysis, with a focus on highlighting the crucial applications of ultrapure water in these processes.

1. Overview of Electrolysis for Hydrogen Production

Electrolysis for hydrogen production encompasses alkaline electrolysis, PEM electrolysis, and solid oxide electrolysis. Among them, alkaline electrolysis technology is mature, cost-effective, and economical. Meanwhile, PEM electrolysis has become the mainstream technology due to its adaptability to renewable energy fluctuations and higher energy conversion efficiency. With the decreasing cost of renewable energy, electrolysis for hydrogen production shows immense potential for cost reduction.

2. Analysis of Hydrogen Production Electrolysis Costs

The costs of electrolysis for hydrogen production include equipment costs, energy costs, raw material expenses, and other operational costs. Alkaline and PEM hydrogen production technologies tend to have higher operational and equipment costs. However, as renewable energy prices decrease and technology advances, the cost of electrolysis for hydrogen production is expected to decrease, making it more economically viable.

3. The Crucial Role of Ultrapure Water in Electrolysis for Hydrogen Production

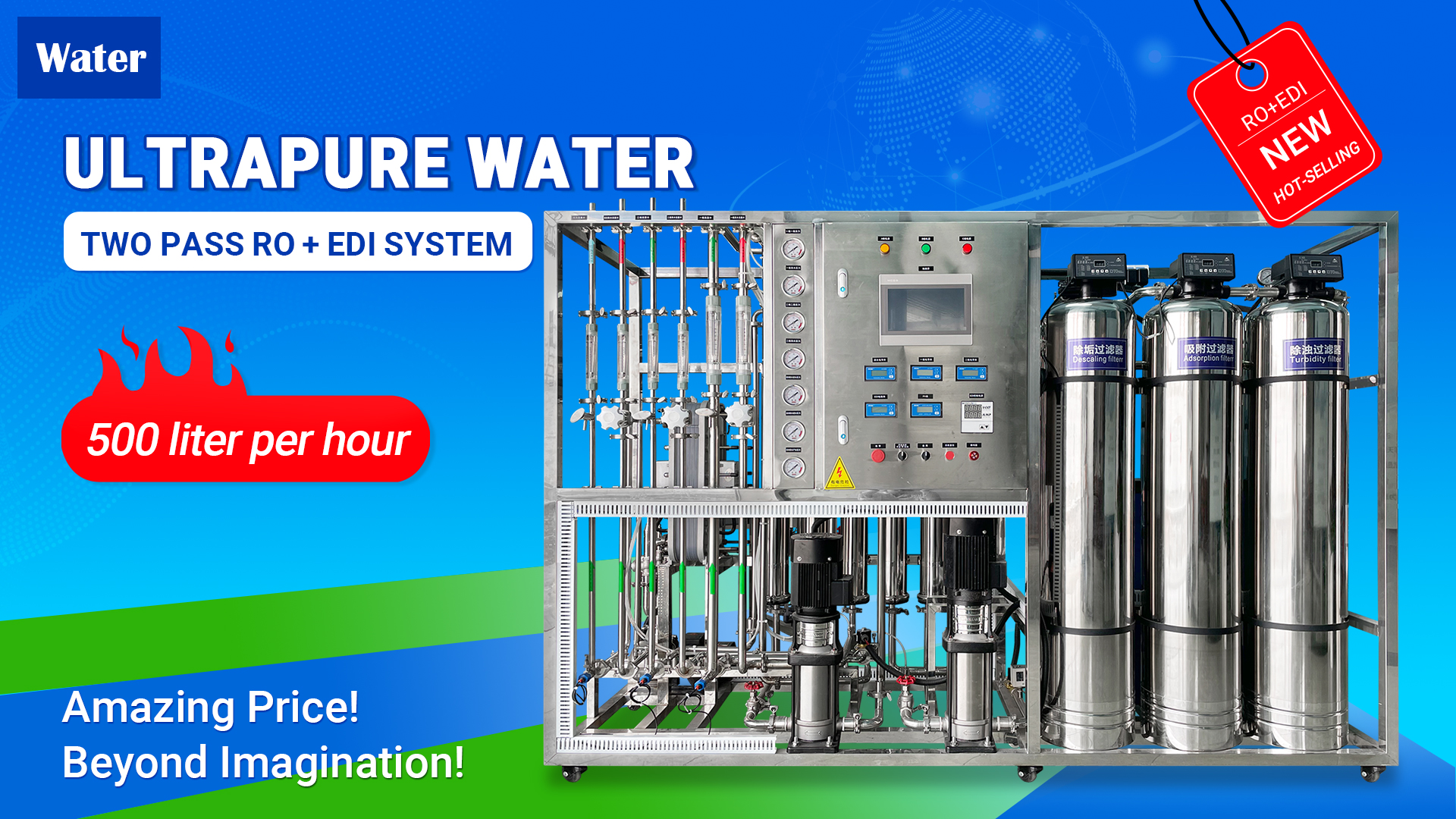

Ultrapure water plays a vital role in ensuring the purity of the electrolysis process. Through pretreatment, reverse osmosis technology, ultrapurification processes, and post-treatment, ultrapure water achieves a resistivity of up to 18.3 MΩ*cm, removing virtually all conductive impurities, colloidal substances, gases, and organic matter from the water, ensuring the purity of the hydrogen gas.

4. Characteristics and Production Process of Ultrapure Water

Ultrapure water is widely used not only in the hydrogen production industry but also in biotechnology, pharmaceuticals, and automotive fields. The production process involves pretreatment, reverse osmosis technology, ultrapurification processes, and post-treatment to ensure the high purity and excellent taste of the water.

5. Conclusion

With continuous innovation in electrolysis technology and the widespread application of ultrapure water equipment, the hydrogen production process will become more efficient, environmentally friendly, and cost-effective. The critical role of ultrapure water positions it as a significant driving force behind the development of hydrogen production technology. In the future, with ongoing technological advancements, we can expect to see further cost reductions in the hydrogen production process, ushering in a new era of development for hydrogen production technology.